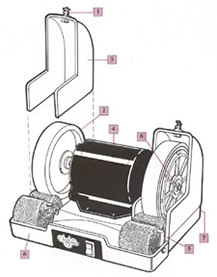

1. Coolant: Two wide-spray valves with compression fittings for applying coolant

2. Speed: 1725 RPM which is perfect for 8" diamond wheels

3. Wheel Guards: Molded plastic wheel guards snap in and out of position for quick removal

4. Motor: 1/2 HP high-torque, permanent split capacitor motor, which is totally enclosed and slealed ball bearing

5. Sponges: Sponge retainer allows adjustment of sponges for any wheel size to reduce excess spray

6. Base: A 3/8" thick powdercoated aluminum casting for easy cleaning

7. Drains: Each coolant well includs an 8' x 5/8" diameter drain line

8. Drive Assembly: Extremely high tolerances on the shafts and wheels eliminate vibration - essential for a fine finish

Glass Grinding

For glass, the most popular wheels for roughing and smoothing are 100 grit and 600 grit. For beveling, 8" wheels are used primarily and the 4" wheels are kept for tight inside curves. An 8" wheel will generate an inside curve as small as a 11/2" radius. 6" & 4" wheels produce an inside radius as small as 1" and 1/2" respectively.

For hot-glass workers, the B3 fitted with radius wheels is perfect for removing punty marks. Many glass workers have diamond wheels mounted on the same shaft with stones or polishing wheels. Consequently, the diamonds are turning much too slowly. Production can be tripled by putting the roughing wheel on one side of the B3. On the other side, use a fine grit diamond for smoothing, instead of a stone, and gain even more time. |