|

|

| Products > Reference > Free Information Pages |

| Air Compressors - general information |

Our Sandblasting and Bevel product lines are sold direct to you from Glastar Corporation -

To ORDER NOW or for more information on these products, e-mail your Wish List to Glastar, or call (800) 423-5635 or (818) 341-0301 (fax) 818 998 2078.

|

|

|

NOTE: Glastar does not sell air compressors. The following information is to assist you in choosing the right compressor to match your sandblaster.

An air compressor is necessary to power the blaster, no matter what kind of blaster you have. The output of the compressor must be matched to the air consumption of the sandblaster for the best efficiency.

The air consumption of any blaster can be figured from the air requirement chart on the nozzle page. Find the nozzle size that comes with the blaster. The chart will tell you the CFM required for continuous blasting at a given pressure. As you use the nozzle, the orifice will enlarge rather quickly, consuming ever increasing amounts of air. The nozzle will enlarge to the point where it is consuming more air than the compressor produces. The compressor will run constantly, losing pressure and overheating in the process. When the compressor runs almost continuously, it is time to replace the nozzle in order to save wear on the compressor. A small compressor will save money initially, but it will cost far more in wasted time waiting for the compressor to catch up.

|

|

Most people doing decorative sandblasting use 2HP to 5HP compressors and pressure blasters with 3/32" nozzles. Using a 2HP compressor and silicon carbide as an abrasive, a nozzle will enlarge to the point where it needs to be replaced in about an hour. An industrial 5HP compressor provides enough air so you could use the nozzle 2-3 hours. If you only blast 6 hours per week, you would purchase 312 nozzles in a year with the 2HP compressor or only 156 with the 5PH compressor. At approximately $3.25 per nozzle, the 5PH compressor will save you about $507 per year. Those savings alone would pay off the extra cost of a 5HP compressor in 3 years. |

|

|

Air Compressor Comparison Table

|

|

Model

|

HP

|

Volts @ 60 Hz

single phase

|

CFM

|

Wt.(lbs.)

|

Pump RPM

|

Config.

|

Size

L x W x H

|

Tank in gals.

|

Compressor

Type

|

Starter

included

|

|

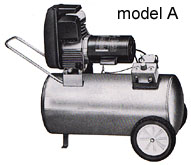

A

|

2

|

115

|

5 @

100 psi

|

118

|

1700

|

portable

|

36 x 21 x 33

|

20

|

single stage

direct drive

|

N/A

|

|

B

|

5

|

230

|

9.5 @

100 psi

|

290

|

932

|

vertical

|

22 x 29 x 33

|

60

|

single stage

belt drive

|

no

|

|

C

|

5

|

230*

|

16.5 @

170 psi

|

452

|

1700

|

vertical

or horizontal

|

39 x 30 x 78 OR

68 x 22 x 48

|

80

|

two stage

direct drive

|

motor

starter

|

|

D

|

5

|

230*

|

15.8 @

170 psi

|

806

|

700

|

vertical

or horizontal

|

25 x 33 x 79 OR

68 x 23 x 51

|

80

|

two stage

belt drive

|

magnetic

starter

|

*Three phase also available. All 5 hp units have ASME Code Tanks

- Model A - A light duty compressor for use where 230 volts is not available.

- Model B - A light duty compressor for shops doing only a small amount of blasting.

- Model C - A light duty commercial compressor for shops doing a moderate amount of blasting.

- Model D - A heavy duty commercial/industrial compressor for use on a heavy continuous basis for many years.

TOP of page

|

|

|

|

Glastar ~ 8425 Canoga Ave. ~ Canoga Park, CA 91304 ~ U.S.A.

phone: 818.341.0301 · toll-free: 800.423.5635 · fax: 818.998.2078

|

|